Tronstol A1 Pick and Place Machine with Semi-Automatic Solder Printer YS 350 and Tronstol Reflow Oven L5 - Economical Assembly Production SMT Line.

Tronstol A1 Pick and Place Machine with Semi-Automatic Solder Printer YS 350 and Tronstol Reflow Oven L5 - Economical Assembly Production SMT Line.

| Model | YS350 |

| PCB size | Max:400*240mm |

| Printing area | 500*320mm |

| PCB fixed system | Pin positioning |

| Frame size | L(550-650)*W(370-470) |

| Adjusting for table | front/rear±10mm,left/right±10mm |

| Printing Accuracy | ±0.2mm |

| Repeating Accuracy | ±0.2mm |

| PCB thickness | 0.2-2.0mm |

| Air source | 4-6kg/c㎡ |

| Power supply | AC220V 50HZ |

| Dimension | L800*W700*H1700mm |

| Packing size | 1050*900*1850mm |

| Net weight | 230kg |

| Gross weight | 280KG |

1. It is controlled by PC, touch screen display and menu interface

2. It uses floating scraper, similar to the automatic printer, scraper can float up and down freely. It can automatically adjust to the level with the steel grid.

3. You can change the length of the scraper to adjust the pressure of the scraper.It is very important to choose the suitable pressure of the scraper.This will influence the precision of solder paste printing.

4.The process of removing the Strip from the PCB can be adjusted between 0 and 5 seconds.

5.Press the button with both hands to ensure safety and reliability.

6.The Stop Time of the scraper on the top left, bottom left, bottom right and top right and the total stop time of the steel bar at the top or bottom can be set independently in the touch screen menu.

7.The PCB can be located and fixed by bottom hole, bottom edge, bottom hole and bottom edge and template positioning.

8.The time can be displayed on the touch screen and the printing time can be recorded.

9.Left and right scraper speed can be adjusted, in case of emergency can be stopped.

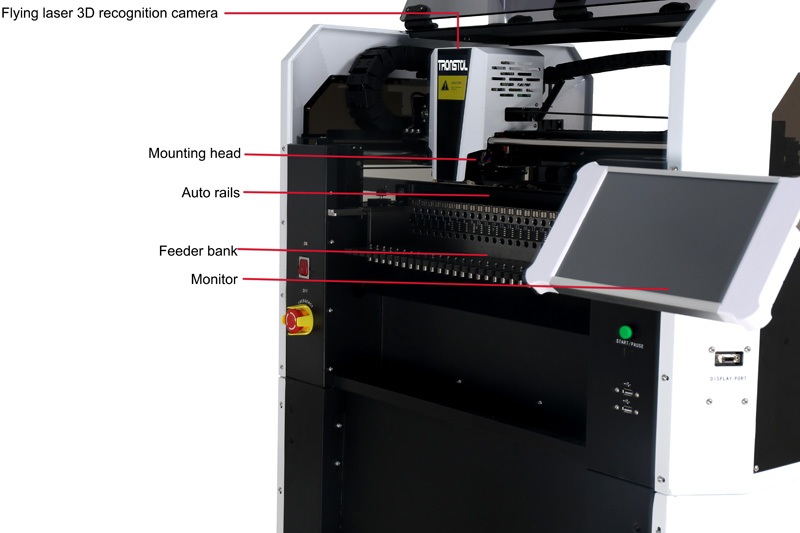

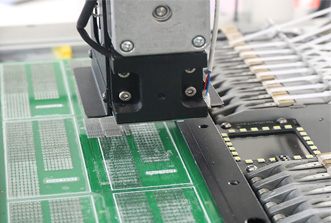

A1 small high-precision pick and place machine,the minimum component can support 0201, equipped with flying laser 3D recognition camera, industrial-grade bus architecture, based on CAN hardware LIN bus. A1 is not only a pick and place machine, but also an intelligent pick and place platform.

| Model | Tronstol A1 |

| Number of Heads with Vision enabled | 4 |

| Placement Rate | 6000PCS/H (vision on) |

| Feeder Capacity | Tape Reel Feeders:58 |

| Tape width | 8mm,12mm,16mm,24mm |

| Vibration Feeder | 5 |

| IC Tray Capacity | 94 |

| Smallest Component size | 201 |

| Largest Component size | 35x35mm |

| Applicable Components | 0201,BGA,SOlc,sSOP,QFN,TQFP,Led PROGRAMMING/MANUAL MECHANICAL |

| Component Height Maximum | 8mm |

| Rotation | +/-180(360) |

| Positioning Accuracy | +/-0.02mm |

| Placement Area | 310*1500mm |

| Programming | SOFTWARE AUTOMATIC PROGRAMMING/MANUAL MECHANICAL PROGRAMMING |

| Power Supply | 220V/110V |

| Power | 150W |

| External Dimensions | Machine:101*88*135CM |

| Net Weight | 98KGs |

1.Flying 3D Laser identification and Correction Technology,Grating Full Feedback System.

2.Accurately handle the components 0201.

3.The automatic feeder stack calibration can greatly save manual calibration time.

4.With independent feed bank,the line change can be completed in 1minute.

1. L5 as the basic reflow soldering, it can meet the needs of general customers. Reflow oven uses hot air to weld PCB, which has good welding effect and low price.

2. L5 is vertical reflow soldering. It has a total of five heating zones, the upper three and the lower two are matched. The temperature curve of composite solder paste can meet the welding effect of components.

3. The conveyor belt is driven by AC motor, which is easy to operate. The speed console can stabilize and customize the temperature according to your needs. The sensitivity is less than 1 degree and the control accuracy is ± 10 mm / min.

| Model | L5 |

| Components Max Height (CM) | 5.5 |

| Conveyor Width(CM) | 30 |

| Max Speed of Conveyor (CM) | 120 |

| Peak Power(KW) | 7 |

| Working Power(KW) | 3 |

| Input Voltage(V) | 380/220 |

| 5 heating zones | First: Fast preheat zone,Second: Soldering zone,Third: Drying zone,Fourth/Fifth: Bottom-side heat zones,(Each zones adapts independent heating/cooling control ways, cooling zone belongs to strong wind refrigerating system.) |

| External Dimensions | Machine:170*70*128CM |

| Net Weight | 210KGS |

| Gross weight | 340kg |

SMT設置機の操作及び設置ヘッドの選択

SMT設置機の操作及び設置ヘッドの選択

E 1は、メモリとピックアンドプレースマシンです

E 1は、メモリとピックアンドプレースマシンです